Plastic injection molding is one of the most cost-effective and scalable manufacturing methods for producing plastic parts. But understanding how much it costs—and what influences that cost—is crucial for making informed decisions.

In this guide, we break down the plastic injection molding cost, explore key pricing factors, and offer tips on how to reduce expenses without compromising quality.

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where molten plastic is injected into a mould cavity under high pressure. Once cooled, the part solidifies into its final shape.

This method is commonly used to create high-volume and high-precision parts for industries such as automotive, medical devices, electronics, and consumer goods.

How Much Does Plastic Injection Molding Cost?

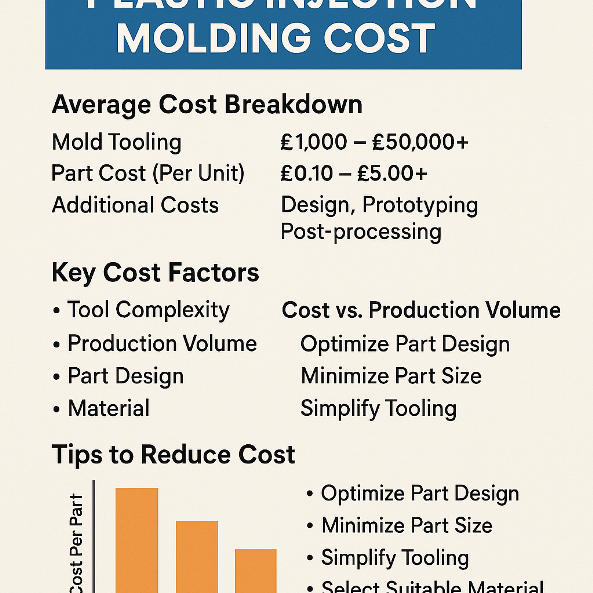

The cost can vary widely depending on several factors. On average, in the UK:

- Mould tool cost: £1,500 to £50,000+ (one-time cost)

- Per-unit part cost: £0.05 to £5.00+ (volume dependent)

- Design and prototyping: £500 to £5,000 (optional but common)

- Post-processing/assembly: £0.10 to £2.00 per part

So, a complete project could range from a few thousand to tens of thousands of pounds, especially when tooling is involved.

Key Factors Affecting Injection Molding Cost

1. Tooling (Mould) Cost

Tooling is typically the largest upfront cost. It includes the design and manufacture of a custom metal mould, often made from steel or aluminium. The complexity, size, and material of the mould greatly influence the price.

- Simple tools: £1,500 – £5,000

- Medium complexity: £5,000 – £20,000

- Highly complex tools: £20,000 – £50,000+

Steel moulds are more durable but cost more than aluminium ones.

2. Production Volume

The more parts you produce, the lower your cost per unit becomes. This is due to the high fixed cost of tooling being spread over many units.

| Quantity | Estimated Cost Per Part |

|---|---|

| 100 | £2.00 – £5.00 |

| 1,000 | £0.50 – £2.00 |

| 10,000+ | £0.05 – £0.50 |

3. Part Design Complexity

Intricate designs, tight tolerances, or multiple cavities in the mould can significantly increase the cost due to longer tool-making and setup times.

4. Material Type

Different plastics vary in price and processing difficulty. Examples:

- ABS: Affordable, commonly used

- Polycarbonate: Tough, more expensive

- Nylon: Strong, versatile

- Medical-grade polymers: Higher cost due to certification

Material selection affects not just cost but also mould design, cooling time, and cycle duration.

5. Cycle Time and Labour

Cycle time refers to how long each part takes to mould and cool. Faster cycles reduce per-unit costs. Automated moulding lines further cut labour costs.

6. Secondary Operations

Costs may increase if parts require:

- Trimming or deburring

- Painting or coating

- Ultrasonic welding

- Assembly

Example Cost Breakdown

For a simple consumer electronics housing (mid-volume run):

- Mould Tooling: £8,000

- Per-part Cost: £0.60 (at 10,000 units)

- Total Cost: £8,000 (tooling) + £6,000 (parts) = £14,000

For 100,000 units, the cost per part could drop below £0.20.

UK vs. Overseas Injection Molding Costs

| Factor | UK Providers | Overseas (e.g., China) |

|---|---|---|

| Tooling Cost | Higher (£) | Lower (£) |

| Shipping Time | Faster (2–3 days) | Longer (2–6 weeks) |

| Communication | Easier (local time) | Time zone challenges |

| Quality Standards | Often higher | Varies by supplier |

| IP Protection | Stronger | Potential risk |

Overseas manufacturing may reduce upfront costs but consider the total cost, including logistics, quality assurance, and risk.

Tips to Reduce Injection Molding Costs

- Optimise Your Design

- Use draft angles

- Avoid undercuts

- Minimise wall thickness variations

- Choose the Right Material

- Avoid over-specifying

- Use standard, readily available plastics

- Use a Single-Cavity Mould (for low volumes)

- Cheaper and faster to make

- Partner with Local Manufacturers

- Saves on shipping and lead time

- Easier communication during iterations

- Get Multiple Quotes

- Always compare prices and check for hidden costs

- Consider Bridge Tooling

- Use aluminium tools for shorter runs before committing to steel

When Is Injection Molding Worth the Cost?

Injection molding is cost-effective when:

- You need large quantities (1,000+ units)

- Your parts require tight tolerances and high repeatability

- Tooling investment can be offset by production volume

- You need a durable and scalable production method

For smaller volumes or frequent design changes, 3D printing or urethane casting may be better alternatives.

Final Thoughts

Understanding the plastic injection molding cost is vital for accurate budgeting and production planning. While tooling presents a significant upfront investment, the long-term savings in high-volume production are substantial.

Whether you’re launching a new product or scaling up, carefully considering design, materials, and supplier location can help you balance quality and cost effectively.

Related Search Keywords for SEO

- Injection moulding UK cost calculator

- Custom plastic parts manufacturing

- Low-volume injection molding UK

- Tooling cost for plastic injection

- UK injection moulding service providers

- ABS injection moulding pricing

Would you like this turned into a downloadable pricing guide or interactive calculator?