Custom CNC machining services play a critical role in today’s manufacturing landscape, offering unparalleled accuracy, flexibility, and efficiency. Whether you’re developing prototypes, producing high-performance components, or scaling your operations, CNC machining provides a reliable, scalable solution tailored to your specific needs.

In this article, we’ll explore what custom CNC machining is, how it works, the industries it supports, and how to choose the right partner in the UK.

What Is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to direct the movement of tools and machinery. It allows for the precise creation of components by cutting, drilling, milling, or turning raw materials such as metals and plastics.

When these services are customised, it means the parts are made exactly to your specifications—no generic templates, just purpose-built results based on your CAD files.

Types of CNC Machining Services

Custom CNC shops typically offer a range of machining processes:

- CNC Milling: Removes material using rotating cutting tools. Suitable for flat and complex surfaces.

- CNC Turning: Produces cylindrical parts by rotating the material against a cutting tool.

- CNC Drilling: Delivers high-accuracy hole placement with custom diameters and depths.

- EDM (Electrical Discharge Machining): Ideal for hard metals and intricate shapes.

- Surface Grinding: Achieves high precision and smooth finishes.

These can be used individually or in combination depending on the complexity of the part.

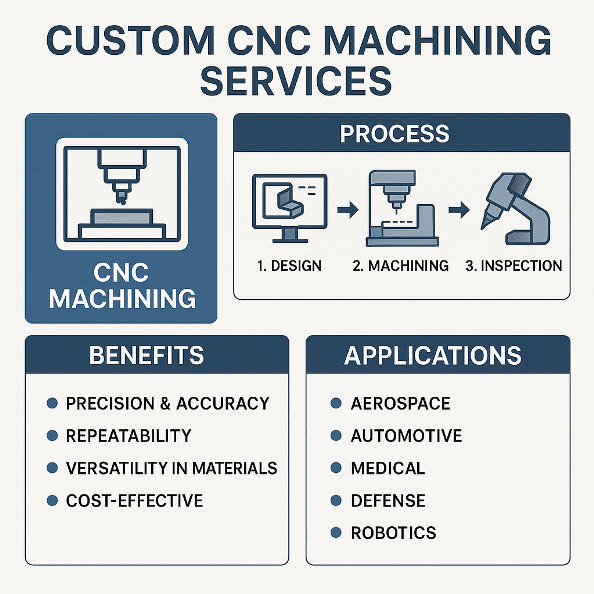

Key Benefits of Custom CNC Machining

Precision and Consistency

CNC machining offers extreme accuracy, often within microns. This makes it ideal for components that require tight tolerances.

Efficiency and Speed

Once programmed, CNC machines work quickly and consistently, allowing for fast turnaround times even on complex parts.

Versatility

Custom CNC services support a wide variety of materials, including:

- Aluminium

- Stainless steel

- Brass

- Titanium

- Plastics such as ABS, nylon, and PEEK

Repeatability

Every part produced will be exactly like the first—essential for applications in aerospace, medical, and automotive sectors.

Cost-Effective for Prototypes and Small Runs

While large production runs benefit from CNC’s speed, it’s also efficient for low-volume or one-off parts due to reduced setup times and rapid prototyping capabilities.

Common Industries That Use CNC Machining

CNC machining is used wherever precision is critical. Examples include:

| Industry | Applications |

|---|---|

| Aerospace | Engine parts, housings, control components |

| Automotive | Gears, transmission components, brackets |

| Medical | Implants, surgical tools, diagnostic devices |

| Defence | Custom weapon components, enclosures |

| Electronics | Circuit board housings, connector pins |

| Robotics | Structural frames, actuators, joints |

The CNC Machining Process

Here’s what a typical custom CNC order involves:

- Design Upload

Submit your 2D/3D CAD files to the machining provider. - Feasibility Analysis

Engineers review your design for manufacturing compatibility and may suggest design improvements. - Quotation and Timeline

You receive a detailed quote, including lead time, material cost, and delivery options. - Machining

The approved design is converted into machine code. Cutting, shaping, and finishing take place. - Quality Inspection

Each part undergoes quality checks using CMM (Coordinate Measuring Machines) or other methods. - Shipping

Final parts are packaged and shipped, often within days.

Choosing a CNC Machining Partner in the UK

Selecting the right CNC service is crucial to product quality and project success. Here’s what to look for:

- Technical Capabilities

Ensure the provider can meet your material, tolerance, and finish requirements. - Certifications

Look for ISO 9001 or AS9100 certifications that demonstrate quality assurance. - Industry Experience

A provider familiar with your industry is more likely to understand and anticipate your needs. - Speed and Scalability

Can they handle urgent orders or scale to full production when needed? - Customer Service

Responsive support and technical advice can make the process smoother, especially during prototyping.

Leading CNC Machining Providers in the UK

Some well-established UK-based CNC service providers include:

- Protolabs UK – Known for quick-turn CNC and prototyping.

- Penta Precision – Offers high-precision parts for medical and aerospace clients.

- Geomiq – A digital platform for on-demand manufacturing.

- Paragon Rapid Technologies – Combines CNC with additive manufacturing services.

Final Thoughts

Custom CNC machining services give manufacturers the precision, reliability, and flexibility needed to stay competitive. Whether you’re building a prototype, producing limited runs, or scaling full production, CNC machining allows you to create tailored components with exceptional consistency and speed.

By choosing a reputable UK provider, you also gain the benefits of local support, faster shipping, and adherence to stringent quality standards.

Related Search Terms

To improve SEO and content relevance, here are some semantically related keywords:

- Bespoke CNC components

- UK precision machining

- Low-volume CNC production UK

- ISO-certified CNC services

- Custom aluminium parts

- On-demand CNC machining

Would you like this turned into a downloadable PDF or formatted for a product landing page?